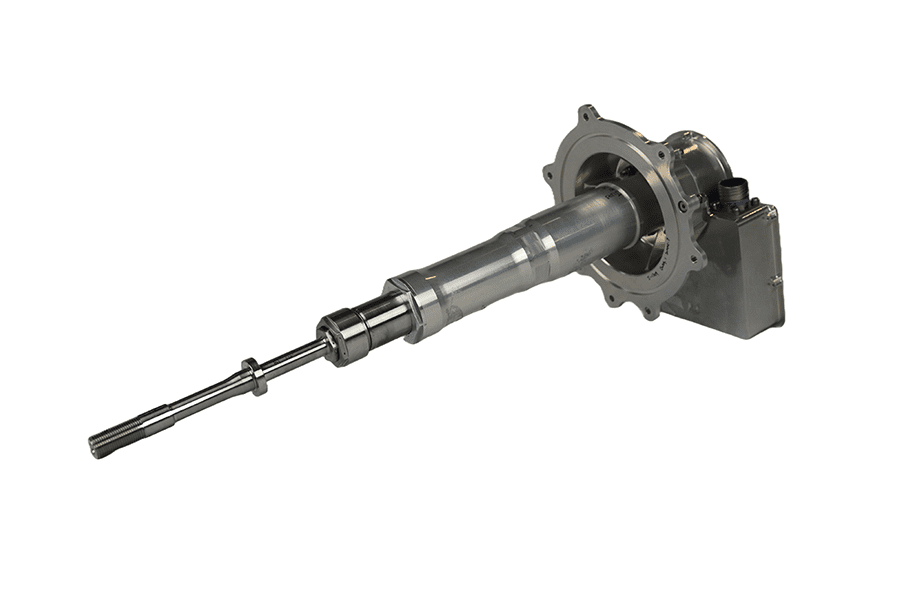

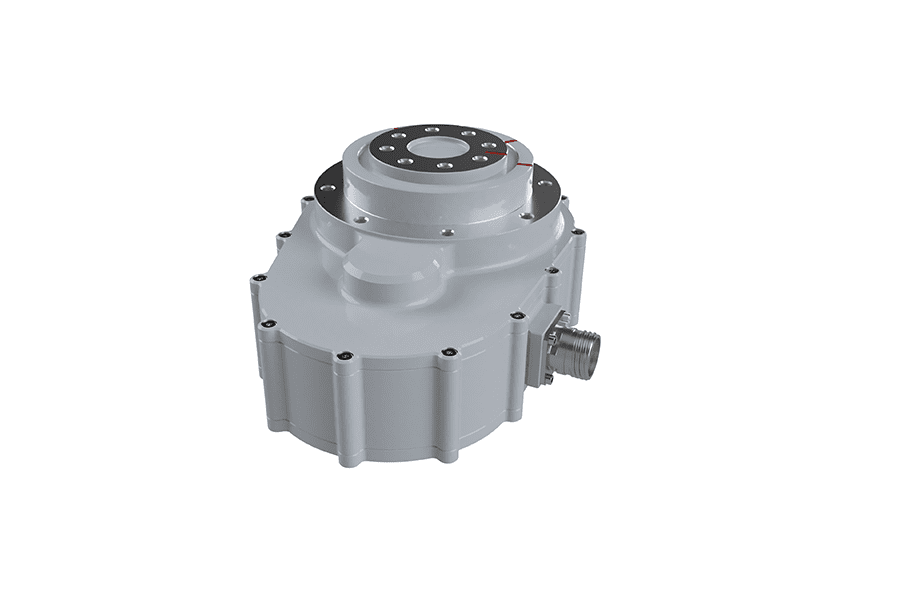

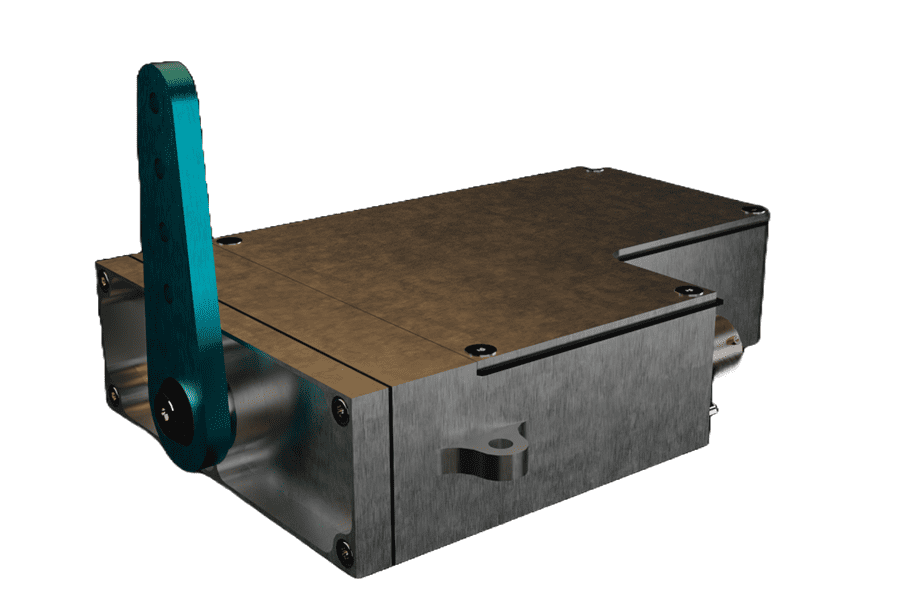

Fully bespoke solutionsSubsea Actuator

After meeting at the Undersea Defence Technologies (UDT) exhibition, an international defence prime engaged Olsen Actuators & Drives to develop a replacement Electromechanical Actuator (EMA) for a legacy unit that was failing due to water ingress, reduced performance, and high maintenance costs. The application was technically demanding, requiring a very compact actuator (<50 mm diameter, <500 mm length), capable of delivering up to 1 kN force while withstanding subsea pressures of up to 7 bar. Leveraging extensive experience in aerospace, defence, and subsea applications, Olsen developed a compliant EMA concept that met and exceeded performance requirements.

Following Concept approval, Preliminary and Critical Design Reviews were completed, covering requirements compliance, interfaces, calculations, materials, and safety-critical aspects. The project then progressed through integration, testing, and verification. Acceptance testing was completed at Olsen’s Preston Brook site, with qualification subsea pressure testing conducted at a UKAS ISO 17025 facility. All actuators were fully tested in line with AS9100 processes and delivered on time, ahead of system-level trials. The client confirmed the solution met expectations and praised the collaborative, high-quality delivery, leading to opportunities for further programs.