Application

Moulding hearing aid inserts.

The Challenge

Whether for vacuum cleaners, hearing aids, or blood filters, engineers who design the tool systems for injection moulded plastic parts face challenges familiar to everyone: “How fast; how accurate; how long; and (like always) how much?” In many cases, the right answer to each of these questions has been made possible by re-evaluating the role that hydraulics have traditionally played in that arena.

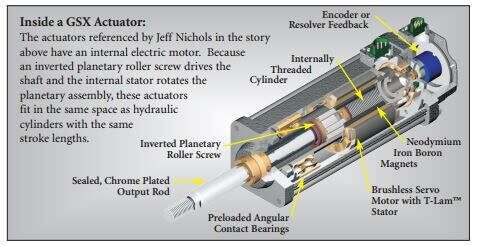

For generations, hydraulic cylinders were the motion control devices of choice for mouldmakers. But today, when it comes to creating the precise, rapid motions that typically happen in these moulds, electro-mechanical actuators with integrated motors (like the Exlar GSX Series) are getting more attention. According to Jeff Nichols, President of ASIC Corporation, a systems integrator headquartered in West Chester, OH, “In many respects, mouldmaking is about creating voids. It’s easy to put resin where you want it — the trick is making sure nothing goes where something else needs to be later.”

It’s a boy-girl thing. Moulds are generally male/female assemblies where the male (or core) forms the finished part’s concave surface. It creates the all-important “nothing”. On a laptop shell, that void houses the electronics; on a plastic plate the voids create separate places for baked beans and potato salad.

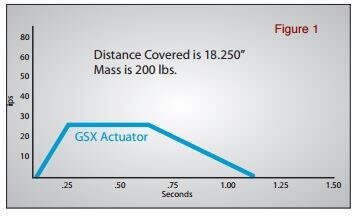

Cycle time is where money gets made. Volumetrics, gate design, temperature controls … mould makers use a host of tools to fill a mould quickly. But after that’s done, the mould still has to be cycled. How fast the core can be moved in and out impacts production. Traditional hydraulic cylinders are fast. But ASIC reports that in some applications, a GSX actuator can enhance cycle rates by letting related operations get started sooner. This is possible because this kind of actuator constantly feeds the core’s actual position and motion status back to the controller.

Longer tool life is an added benefit. “Every time we can replace a hydraulic cylinder with an Exlar electromechanical actuator, we can virtually guarantee a longer tool life.” Nichols continued, “That actuator lets us get the core inserted faster without just slamming the mould together violently. Less stress means longer life.”

Due to a closed loop feedback system, GSX linear servo actuators can be programmed with a desired velocity rate and accel./decel. ramping. This enables the user to optimize product throughput and machine life.

Retasking the same actuator on different projects is easy. Especially in retrofit situations, ASIC always addresses reuse in their cost analysis. According to Nichols there are cases where an actuator spec’d for one mould has more power than needed because it could be reused on another assembly that did require that additional power. “These actuators are really simple to retask. You just plug a laptop into the drive, feed it a new motion profile, and it’s ready to go.” said Nichols.

The Solution

So, how difficult is it to retrofit hydraulic cylinders with electromechanical actuators? The Exlar actuators that ASIC uses are truly “plug ‘n play”. A hydraulic cylinder’s two hoses are replaced with a pair of electrical connections. The mounting flanges are all industry standard. And because the GSX has an internal motor, both have the same form factor. Thus, for comparable stroke lengths, the GSX units fit in the same space.

The remote electronics for a GSX actuator require very little space. For IMM mould applications, they’re often put in a small rolling cabinet that sits next to the machine. 1. Line filter, 2. Power supply, 3. Servo controller into which you download the desired motion parameters. (Photo courtesy of ASIC Corp. www.asiccorporation.com)

You need to create a “nothing” exactly where you want it to make most injection moulded plastic parts serve their intended purpose. A typical mould assembly is comprised of 1. Stationary platens, 2. The core, 3. Linear guides, 4. Actuator (or cylinder) rod, and 5. Electro-mechanical actuator or hydraulic cylinder.

Results

The equipment was cleaner, quieter and less expensive to run.

Those aren’t bad goals for any designer; especially if you’re working in a field that’s traditionally plagued by noise and contamination issues.

- Accuracy and Repeatability – hydraulic fluid can heat up, hoses can expand, and valves can stick. These variables all affect accuracy. Digitally controlled mechanical drives are more accurate over the long haul because they don’t use those components.

- Set-up Precision – digital control permits operators to set tighter over/under tolerances.

- Utility Costs – Milacron identified a 50-90% power reduction when they compared their own comparably sized all-electric and hydraulic IMMs. The actual connected power requirements for their all-electric machines were just 25% of that needed by their hydraulic equivalents.

- Oil Costs Eliminated – not only is the initial cost of oil purchase removed from the cost equation, but so are the ongoing costs for monitoring, disposal and clean ups.

- Cleanroom Ready – By eliminating the possibility of oil leaks, Milacron pointed out that an all-electric machine became the obvious choice for a host of medical, electronic and other such cleanroom applications.

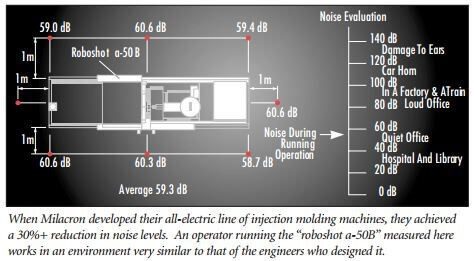

- Noise Levels – Plant noise is always under scrutiny from workers’ compensation insurance agencies. By replacing hydraulics with electromechanical motion controls, noise levels on the new Milacron machines dropped by over 30%.

A complete copy of the original Milacron paper can be downloaded at: http://plastics.milacron.com/