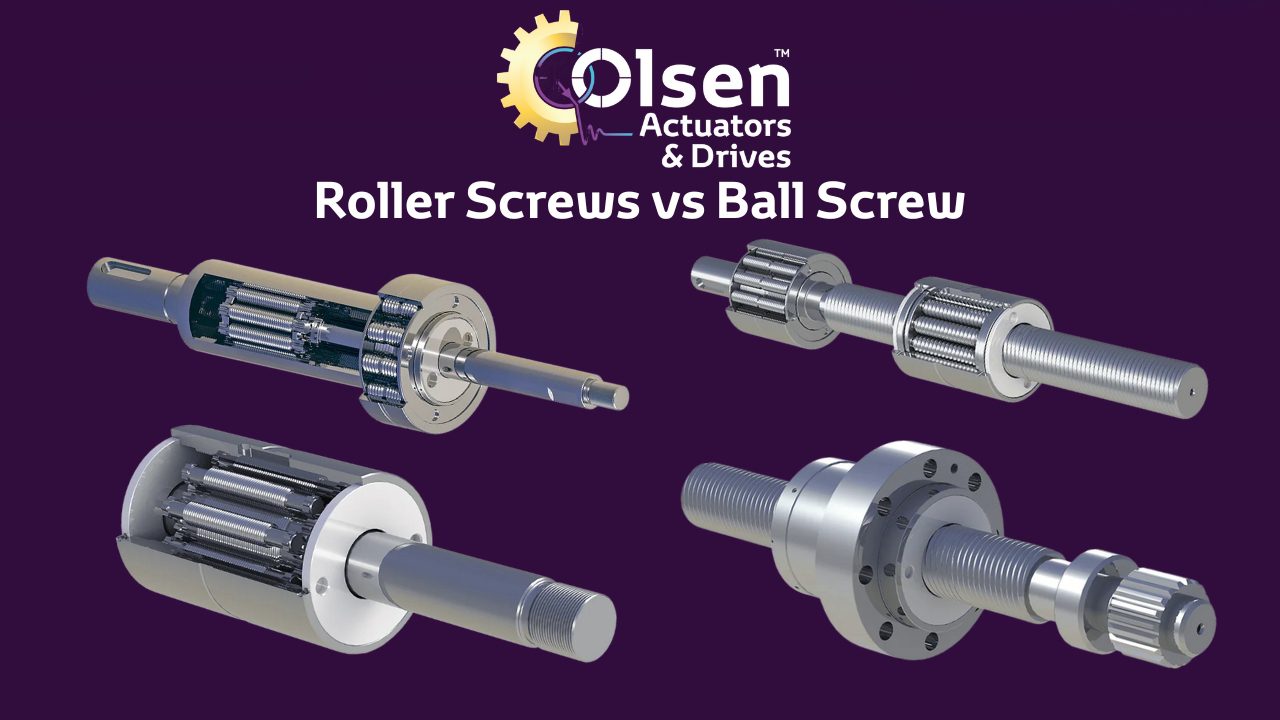

When designing high performance linear motion systems, engineers often find themselves comparing roller screws and ball screws. Both technologies convert rotary motion into precise linear movement, but the differences in load capacity, durability, accuracy, and service life can be dramatic. Understanding these differences will definitely help you decide on an actuator that delivers the performance for your application.

At Olsen Actuators and Drives, we design and manufacture roller screw driven electro-mechanical actuators. This article breaks down the key differences so you can make an informed choice with our partners ALT Bearings in France.

What is a Ball Screw?

A ball screw uses recirculating ball bearings running between the screw shaft and nut. These rolling elements drastically reduce friction compared to traditional lead screws and allow for efficient, repeatable linear motion. Used in industries like Aerospace, Medical, Automotive and manufacturing.

What Is a Roller Screw?

A roller screw is elegantly simple yet highly a highly effective mechanism. Unlike traditional ball screws, roller screws utilise threaded rollers instead of ball bearings. This seemingly subtle modification yields many advantages, making roller screw technology an increasingly preferred choice for engineers and designers seeking optimal performance.

Key Advantages of Roller Screws

- Very high load capacity, far exceeding ball screws

- Exceptionally long service life

- High speed and high dynamic performance

- Superior stiffness, delivering precise positioning

- Ideal for continuous duty cycles or harsh environments

Typical Roller Screw Applications

- Electric presses and high force forming

- Injection moulding machines

- Servo-actuated hydraulic replacements

- Aerospace actuator systems

- Robotics requiring high precision and high load

- When the application is demanding and downtime is costly, roller screws excel.

Why Choose Electric Actuators

Electric actuators are increasingly being used for high-force applications due to their superior performance and efficiency over the traditional ball screw type, offering full control of motion and are fully programmable, making them the ideal for applications requiring precise control. Electric actuators deliver forces up to 350kN, making them suitable for extreme high force and high duty applications.

How we can support you

We design, manufacture, and integrate high performance Electro-mechanical actuators using roller screws. We help you choose the best solution based on your application force, speed, duty cycle, lifetime expectations, precision, and environment.

To find out more speak to our team:

info@olsenactuators.com

Phone: 01925 202127