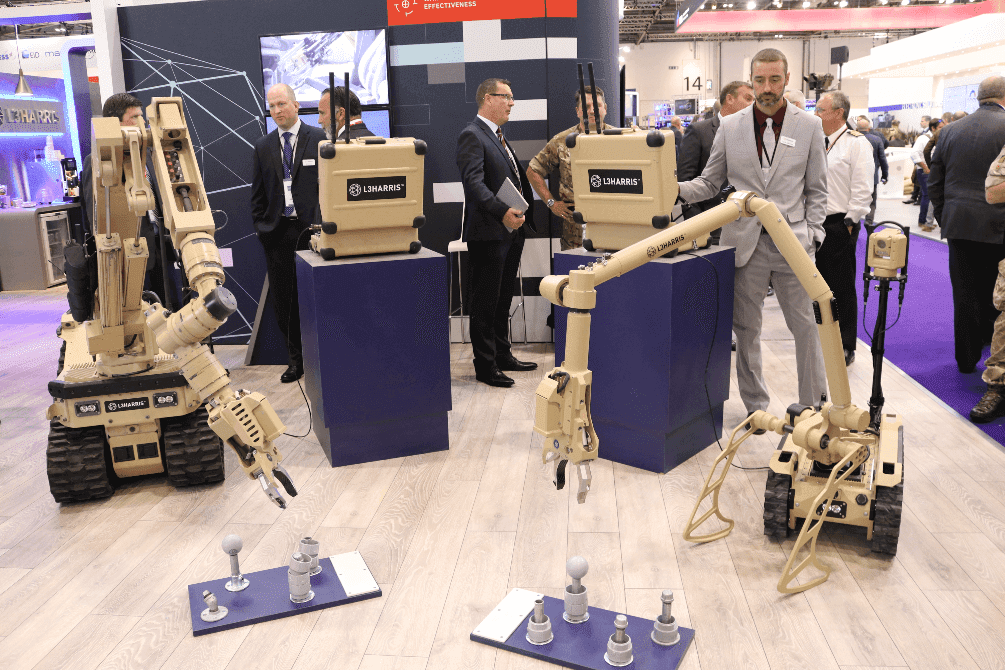

Fully bespoke system solutions

A leading UK test house approached Olsen to design an actuation system that was able to put dynamic loads through various test samples including structural precast concrete. This system needed to reliably operate over millions of cycles and provide an accelerated life test to the samples. Olsen provided a complete system including multiple roller screw actuators and a control panel which was integrated into the customer’s high level control system

o Requirements managed

o Full Factory Acceptance Test at Olsen

o On-site support to customers during integration